Transforming Metal Fabrication Through Precision Techniques

Introduction to Modern Metal Bending

The world of manufacturing is increasingly defined by accuracy, efficiency, and repeatability. In sectors such as automotive, aerospace, electronics, and construction, precise metal components are essential for safety, functionality, and aesthetics. The Precision & Bending industry plays a pivotal role in achieving these goals, ensuring that sheet metal parts are formed with exact angles, uniform dimensions, and minimal material waste.

One of the central technologies in this sector is press brake bending. This process has evolved from manual bending to fully automated CNC systems, enabling manufacturers to produce complex components with remarkable accuracy. Understanding the principles and applications of press brake bending is crucial for modern fabricators seeking high-quality results.

Fundamentals of Press Brake Bending

Press brake bending involves shaping metal sheets by applying controlled force along specific points using a press brake machine. Unlike manual methods, this technology ensures precise control over bend angles, radii, and the overall geometry of a part. The introduction of CNC systems has further enhanced this capability, allowing operators to program multiple bends, adjust parameters on the fly, and maintain consistent results across production runs.

The precision achieved during press brake bending is essential for parts that must fit together in assemblies, such as automotive frames, electrical enclosures, and industrial machinery. Even minor deviations can lead to costly rework or compromised performance, highlighting the importance of both technology and operator expertise.

Material Considerations

Different metals respond differently to bending forces. Stainless steel, aluminum, and carbon steel each exhibit unique springback tendencies, hardness, and surface characteristics. Press brake bending requires an understanding of these properties to ensure that the final component meets design specifications.

Choosing the right tooling and bend parameters is influenced by the material type, thickness, and desired angle. For example, aluminum may require softer tooling to prevent scratching, while high-strength steel needs precise calibration to avoid excessive springback. Skilled operators combine technical knowledge with experience to achieve consistent, high-quality bends.

Role of Technology in Precision Bending

The advancement of CNC press brakes has revolutionized metal fabrication. Modern machines integrate programmable backgauges, angle sensors, and adaptive force control, allowing precise repetition of complex bending sequences. Software simulations can predict springback, collisions, and material behavior before physical production, reducing trial-and-error and saving time.

Automation also improves efficiency by reducing press brake bending setup times, enabling quick changeovers between parts, and lowering the risk of human error. These technological improvements make press brake bending suitable for both high-volume production and intricate, low-volume projects where precision is paramount.

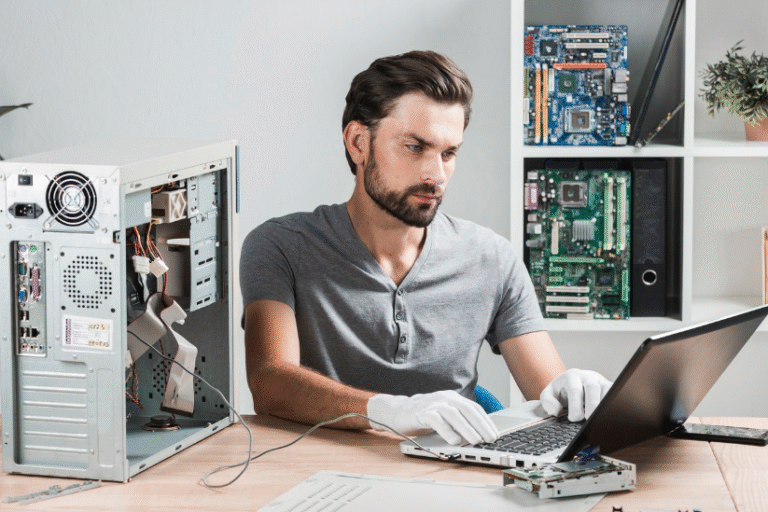

Importance of Skilled Operation

While technology enhances accuracy, skilled operators remain a vital component of the bending process. They interpret technical drawings, select appropriate tools, and make real-time adjustments based on visual and tactile feedback. Experienced operators also monitor machine performance, troubleshoot issues, and ensure that each component meets exact specifications.

Investing in operator training is critical. Training programs cover machine safety, material behavior, and bending techniques, equipping personnel with the expertise needed to maximize the capabilities of press brake bending equipment. Companies that prioritize operator skill often see improvements in product quality, productivity, and overall efficiency.

See also: Your Trusted Partner in Laser Technologies

Quality Control in Press Brake Processes

Maintaining high-quality standards requires systematic inspection during and after bending. Measurement tools such as digital angle gauges, calipers, and laser scanners verify that components meet design tolerances. Implementing rigorous quality control reduces scrap, ensures consistent results, and enhances customer satisfaction.

Quality assurance is especially critical in industries like aerospace and automotive, where even small deviations can affect performance and safety. Consistent press brake bending processes help manufacturers adhere to strict industry standards and regulatory requirements.

Applications Across Industries

Press brake bending is utilized in numerous sectors. Automotive manufacturers rely on it for chassis components, brackets, and panels. Aerospace applications demand exact tolerances to ensure structural integrity and aerodynamic efficiency. Electronics manufacturers use bending to produce precise enclosures, while construction and architecture require it for durable and visually appealing metal frameworks.

In each application, press brake bending enables the production of components that are both functional and aesthetically refined. Its versatility and precision make it an essential technology across multiple industries.

Efficiency and Cost Considerations

Efficiency in press brake bending directly affects operational costs. Automated CNC systems reduce setup time, minimize material waste, and allow rapid part changes. Precision in bending also decreases the need for rework, saving labor and reducing the risk of defective products reaching customers.

Balancing efficiency with quality requires careful planning and the selection of reliable equipment. Companies that invest in advanced press brake bending systems achieve a competitive edge by producing high-quality parts faster and more consistently than competitors relying on manual or older machinery.

Safety in the Bending Process

Safety is a fundamental concern in press brake operations. Modern machines feature light curtains, emergency stops, and ergonomic controls to protect operators from injury. Proper training ensures personnel understand potential risks and follow best practices, reducing workplace accidents while maintaining productivity.

Safe operations also contribute to quality. Operators who work in secure, well-designed environments can focus on precision and efficiency, resulting in superior bending outcomes and a more productive manufacturing process.

Emerging Trends in Precision Bending

The future of press brake bending lies in smart manufacturing technologies. Machine learning, predictive maintenance, and adaptive control systems are increasingly integrated into modern equipment. These innovations allow machines to optimize performance, detect anomalies, and reduce downtime.

Digital twins and simulation software are also transforming the industry. Engineers can model bending processes virtually, identify potential challenges, and refine production parameters before physical fabrication. Such advancements further enhance precision, reduce material waste, and improve overall operational efficiency.

Conclusion

Precision and bending are integral to the modern metal fabrication industry. Press brake bending technology enables manufacturers to produce accurate, high-quality components across a wide range of applications. Combining advanced machinery, skilled operators, and robust quality control ensures that products meet strict industry standards while minimizing waste and cost.

Investing in technology and training allows manufacturers to stay competitive, deliver reliable components, and meet the evolving demands of sectors where accuracy is critical. As the industry continues to embrace automation, simulation, and smart technologies, press brake bending will remain a cornerstone of efficient, high-precision metal fabrication.