What is an Automatic Filling and Sealing Machine?

The automatic filling and sealing machine is a key tool for packaging liquids, pastes, and small solid products. It is widely used for cooking oil, sauces, shampoos, and detergents. This machine fills products accurately, seals them tightly, and keeps them clean, making packaging faster, easier, and more reliable than doing it by hand.

1. Definition and Function of Automatic Filling and Sealing Machine

What is an Automatic Filling and Sealing Machine

An automatic filling and sealing machine, belonging to a certain type of packaging machinery, can automatically complete the product filling and sealing process. The main component structure includes a filling system, conveyor system, sealing system, and control system. Features such as filling volume and method of sealing can be changed based on product characteristics; thus, it is suitable for liquids, pastes, granules, and powders.

- Principal Functions of an Automatic Filling and Sealing Machine

- Efficient filling: Precisely meter the volume in each bag or container, minimizing waste.

- Reliable sealing: It ensures tight packaging, without leakage or contamination.

- Automation: Reduce human interference and enhance production efficiency.

- Flexible adaptation: Suitable for different sizes of packaging and types of containers.

These functionalities help the company improve production efficiency and ensure safety and integrity of the product in transportation and storage.

2. Types and Features of Automatic Filling and Sealing Machine

- Classification by Packaging Form

- Filling and Sealing Machine for Bags: Suitable for pre-made bags containing liquids, pastes, or granules.

- Bottle Filling and Sealing Machine: Suitable for glass, plastic, or metal containers, can use screw caps or heat sealing.

- Carton Filling and Sealing Machine: Suitable for cartons or composite packaging, the machine is often used in the beverage industry.

- Classification by Automation Level

- Semi-automatic machine: Requires manual placement of bags or containers; the machine performs filling and sealing.

- Fully automatic machine: Automates the entire process from feeding, filling, sealing, to finished product output.

- Intelligent machine: Equipped with sensors and a PLC controller that automatically adjusts the volume of filling, speed, and sealing temperature; remote monitoring is possible.

- Key Technical Features

- High-precision filling system accurate to ±1%

- Heat sealing or ultrasonic sealing for strong, reliable seals

- PLC or touchscreen control system for easy operation

- Customized packaging specifications depending on different production requirements

See also: Innovations in Candle Boxes Materials and Technology: Rethinking Packaging Methods

3. Key Factors in Selecting an Automatic Filling and Sealing Machine

Product Characteristics

Product viscosity, particle size, and liquid properties determine the filling method for an automatic filling and sealing machine. High-viscosity liquids, such as cooking oil or pasty products like shampoo, require specialized pumps and filling heads to ensure smooth, accurate flow without overflow.

Packaging Specifications

Notice the size and material of the packaging bags or containers. Fully automatic machines normally support multi-size customization, reducing the frequency of replacing parts and increasing production efficiency.

Production Efficiency

Chose a machine depending on your production demand. Small to medium production lines will require 25-45 bags per minute, while large-scale production will require high-speed machines.

Level of Automation and Intelligence

Fully automatic and intelligent machines reduce manual intervention, lower labor costs, and provide production monitoring through PLC and data acquisition systems, improving management efficiency.

4. Advantages of Automatic Filling and Sealing Machine

- Improved productivity: Automation greatly increases the speed of production, multiplying manual efficiency.

- Product quality and hygiene guaranteed: Reduced contact eliminates the possibility of contamination, while either ultrasonic or heat sealing keeps items airtight.

- Lowering production costs: Reduces labor and material waste while improving production line stability.

- Flexible product adaptation: The same machine can handle liquids, pastes, or granules to meet different production needs.

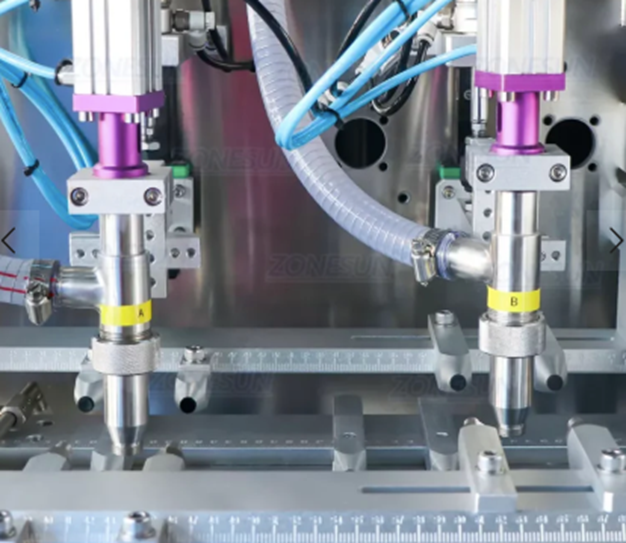

ZONESUN ZS-AFS03 Full-automatic Bag Filling and Sealing Machine

Automatic filling and sealing machines are important in food and daily chemical production to ensure product quality and production efficiency. ZONESUN’s ZS-AFS03 fully automatic pre-made bag packaging machine is the ideal solution. Designed specifically for pre-made bags, it can easily handle yogurt, detergents, shampoos, cooking oil, and other liquids or pastes.

Key Features:

- High productivity: Fills 25-45 bags per minute; suitable for small and medium-scale production lines

- Fully automatic operation: From feeding to sealing, saves much manual labor

- Accurate filling: Adjustable volume per bag, minimal error, reducing waste

- Reliable sealing: High-temperature heat sealing secures packaging

- Customizable design: Accommodates various bag sizes and types

- Wide range of applications: Suitable for yogurt, cooking oil, detergents, shampoo, and other liquid/paste products

This machine increases production efficiency while ensuring consistent product quality and hygiene, making it an ideal choice for modern food and daily chemical production lines.

Conclusion

In summary, automatic filling and sealing machines are indispensable equipment in modern packaging. They improve production efficiency, ensure product quality, reduce costs, and adapt to various packaging sizes and product types. Companies like ZONESUN provide reliable and innovative filling and sealing machine solutions, helping the food and consumer goods industries achieve efficient, hygienic, and stable production.