Brewing Smarter: Proven Strategies to Boost Beer Production Efficiency

In today’s competitive beer industry, efficiency isn’t just a nice-to-have—it’s the key to consistent quality, reduced costs, and stronger profit margins. Whether you operate a small craft brewery or a large-scale manufacturing facility, finding ways to optimize your brewing process can help you keep up with demand while preserving the flavor and character your customers love. Brewing smarter is all about balancing speed, quality, and sustainability without cutting corners.

Here’s a closer look at proven strategies to boost beer production efficiency from mash to market.

1. Streamline Your Brewing Workflow

Every extra step or bottleneck in your process can slow down production and increase costs. Start by mapping your entire brewing process—from ingredient delivery to packaging—to identify inefficiencies.

Some common areas to optimize include:

- Mash and boil timing: Adjust schedules to overlap certain non-critical steps where possible.

- Fermentation monitoring: Use automated temperature controls to reduce downtime caused by inconsistent fermentation conditions.

- Chloride removal: Ensure water treatment systems effectively remove excess chloride to protect flavor consistency and equipment longevity.

- Packaging line flow: Ensure there’s minimal equipment idling between bottling, canning, and labeling.

Small tweaks in sequencing and layout can dramatically improve throughput without requiring major investments.

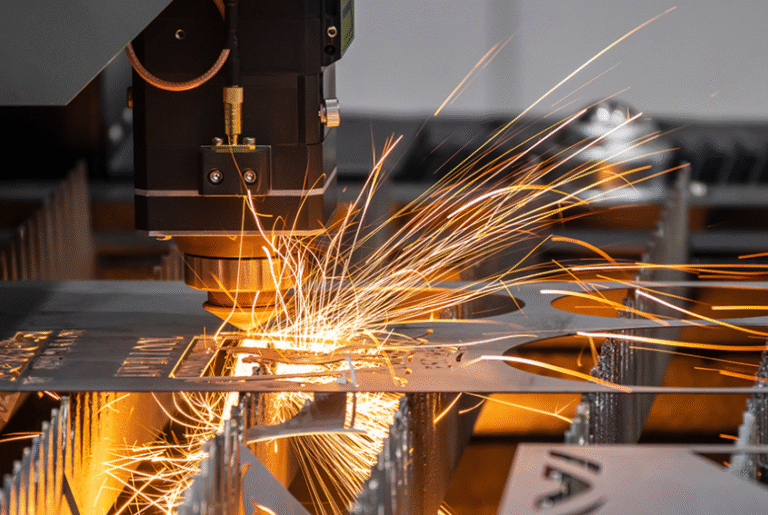

2. Invest in Automation Where It Counts

Automation doesn’t mean replacing skilled brewers—it means freeing them from repetitive manual tasks so they can focus on quality control and innovation.

Examples of effective automation in beer manufacturing include:

- Automated grain milling systems for consistent crush quality.

- CIP (Clean-In-Place) systems to speed up sanitation while reducing water and chemical use.

- Automated filling and labeling lines to maintain steady output without overstaffing.

Even partial automation in specific stages can deliver significant long-term time and cost savings.

3. Optimize Ingredient Usage

Efficiency isn’t only about speed—it’s also about minimizing waste. This starts with careful ingredient management.

- Standardize recipes: Consistency reduces the risk of costly re-brews or flavor discrepancies.

- Weigh and measure precisely: Automated dosing systems can help avoid overuse of hops, yeast, or malt.

- Repurpose byproducts: Spent grain can be sold or donated to farms as animal feed, reducing waste disposal costs.

Not only does this improve your bottom line, but it also supports sustainability goals—a growing priority for today’s beer consumers.

See also: Benefits of Working with a Career Consultant During a Career Transition

4. Improve Energy and Water Efficiency

Beer manufacturing is resource-intensive, and energy or water waste can erode profitability. Efficiency-minded breweries use strategies like:

- Heat recovery systems to capture and reuse heat from the wort boiling stage.

- Insulated tanks and piping to reduce temperature loss.

- Water recirculation systems for cooling and cleaning tasks.

Tracking your energy and water usage per batch can reveal hidden inefficiencies and help you set achievable conservation targets.

5. Prioritize Preventive Maintenance

Equipment downtime is one of the biggest productivity killers in beer manufacturing. Instead of waiting for machinery to fail, develop a preventive maintenance plan.

- Schedule regular inspections of pumps, valves, and fermenters.

- Lubricate moving parts on a set schedule.

- Keep critical spare parts in stock to reduce repair delays.

Preventive maintenance ensures smooth production runs and extends the lifespan of your equipment.

6. Train and Empower Your Team

Even the best equipment can’t make up for a team that’s untrained or disengaged. Regular training ensures your staff can work efficiently, follow safety protocols, and identify potential issues before they escalate.

- Provide cross-training so team members can step into multiple roles when needed.

- Encourage suggestions for process improvements—your brewers and operators often know where inefficiencies hide.

- Foster a culture of quality, where speed never compromises taste.

A motivated, skilled workforce is one of the most powerful tools in improving brewery efficiency.

7. Track and Analyze Key Metrics

What gets measured gets improved. Tracking performance data helps you make informed decisions. Useful metrics include:

- Batch yield percentage – How much beer you get from each batch versus your target.

- Cycle time – How long it takes to go from raw ingredients to packaged product.

- Energy usage per barrel – Helps identify high-consumption processes.

- Downtime tracking – Reveals patterns in equipment failures or delays.

Use this data to pinpoint problem areas, test solutions, and monitor progress over time.

Final Pour: Smarter Brewing for Lasting Success

Boosting beer production efficiency isn’t about brewing faster at all costs—it’s about producing consistent, high-quality beer with minimal waste, downtime, and resource consumption. By streamlining workflows, leveraging automation, managing ingredients wisely, conserving energy and water, and empowering your team, you can create a brewery that thrives in both productivity and quality.

In the end, efficiency allows you to focus on what matters most: delivering great-tasting beer to your customers, pint after pint.