How to Carry Out a Hazard Assessment Step by Step Using the HIRA Approach

One of the most important features of contemporary workplaces is ensuring workers’ health and safety. Workplace accidents occur every year, which cause harm and expenses to companies. The accidents indicate the need for a more contemporary and futuristic system of workplace safety. This is precisely the central issue of HIRA (Hazard Identification and Risk Assessment). HIRA focuses on safety practices that have a priority on prevention, preparation, and proactive safety culture at every organizational level.

Who is Responsible for Conducting a Hazard Assessment?

This process is vital in order to offer compliance with workplace safety and effective management of risks. The respective competent person, in most instances, safety manager with extensive safety training who is responsible for hazard identification. They possess the required expertise to identify actual and potential hazards that can pose a risk to the safety and health of employees in their work environment. Employers are responsible for carrying out hazard assessments in the workplace. Their capacity to act quickly and take corrective measures is essential in averting accidents, injuries, or fatalities. Importance of Hazard Identification and Risk Assessment Hazard identification and risk assessment are critical components of ensuring the security and well-being of persons in various environments, whether at work, at home, or in public places.

With the identification of possible hazards and an assessment of the associated risks, organizations and people can put measures in place in advance to minimize the risk of accidents, harm, or other undesirable events from happening.

This activity guarantees the health and safety of people and also helps protect assets, properties, and the environment. One of the most important reasons why hazard identification and risk assessment are so useful is that they enable one to anticipate and prepare for threats before their occurrence. By taking an orderly approach to detecting hazards, such as through frequent inspections, analyzing historical data, and consulting with stakeholders, one can easily detect the areas one needs to work on and categorize them based on how much threat they pose. This proactive approach not only reduces the likelihood of accidents but also allows resources to be deployed in the execution of control measures that are clearly specific to specific threats, making them more effective. Lastly, hazard identification and risk assessment foster a safety culture and ensure that individuals are better equipped to react to emergencies and unintended events, inducing an overall resilience and well-being.

Steps to Conducting a Thorough Hazard Identification and Risk Assessment

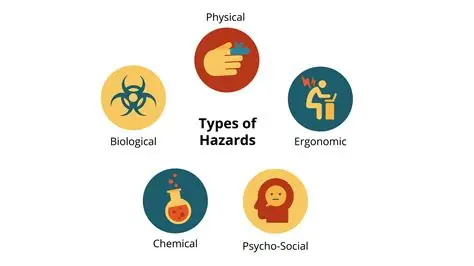

1. Identify Hazards- The first step in the HIRA process is to identify potential hazards in the workplace. They are physical, chemical, biological, ergonomic, and psychosocial hazards. Utilising HIRA allows the organization to be able to systematically gather data from various sources, such as incidents, employees’ comments, and observations. Workplace inspections and engagement of staff members for hazard identification are useful because they provide an effective evaluation.

2. Assess Risks- Following the identification of hazards, the second step is to assess the risk for each hazard. It involves assessing the likelihood that an accident will occur and the potential severity of the effect. HIRA provides risk assessment matrices and criteria for organizations to quantify risks in an organized manner. Clustering the risks facilitates prioritization of activities by severity and likelihood, making it possible to effectively allocate resources.

3. Control Measures- After risk assessment, one needs to establish control measures that will minimize risks caused by the identified hazards. The hierarchy of control should be adhered to, starting with the most potent control. Organizations can develop detailed action plans setting forth some control measures, tasks, and timelines. These control measures may go from elimination of the hazard to substitution of the hazard with less harmful materials, engineering controls, administrative controls, and PPE.

4. Monitor and Review- Monitoring and review of the success of control measures is ongoing. ISO facilitates establishing monitoring systems that periodically monitor the success of implemented controls. Regular audits, inspections, and worker opinions can be included. Additionally, it should be reviewed regularly to update the HIRA to incorporate any changes in the workplace, e.g., new processes, equipment, or staff. Continuous improvement processes guarantee the applicability and efficiency of safety controls.

5. Documentation and Reporting- Adequate documentation of the HIRA process is required for accountability and compliance. HIRA provides guidelines and templates for documenting hazard identification, risk assessment, control measures, and monitoring activities. Reporting the findings to the management and personnel ensures a safety culture and transparency, inviting continued involvement in health and safety practice.

What are the Types of Hazards?

During the performance of a risk assessment, it is good to be aware of the different types of hazards so that one may be able to locate potential risks within an environment. Hazards can be broadly classified into various types, each posing different challenges and risks. The primary types of hazards include physical hazards, chemical hazards, biological hazards, ergonomic hazards, and psychosocial hazards.

Physical dangers are often environmental conditions that can cause harm, such as slippery floors, electric wires that are not covered, or noise that can result in hearing impairment. Chemical dangers encompass any harmful substance, whether it is solid, liquid, or gas and can result in injury or accident. Some examples would be solvents, acids, and gases that are poisonous or flammable.

Biological hazards are organic substances that represent a risk to human health such as, bacteria, viruses, fungi, and other biohazards that may lead to infection or disease. Ergonomic hazards arise from a poorly designed workspace or tool that may lead to musculoskeletal injury. Psychosocial hazards include elements of the work environment that have the capacity to cause stress or mental ill health, such as workplace bullying or workload harassment.

With respect to risk assessment, identifying such hazards is done with a systematic approach. Every type of hazard must be considered based on its occurrence as well as its potential impact on individuals and the overall environment. This assists organizations in implementing the right controls to mitigate the risks ineffective.

There are various systematic techniques that are applied to identify hazards in a risk assessment. Start by gathering a representative number of stakeholders to enable a sufficient appreciation of the environment. Working environment walk-through, interviews with staff, and review of incident reports can uncover obvious hazards. Furthermore, employing industry-specific checklists will aid in enabling consideration of all forms of hazards. With sufficient evaluation of the nature and implications of each hazard, organizations can devise an orderly risk management plan that is cognizant of safety without undermining the effectiveness of operations.

Conclusion

A functioning HIRA is vital to provide a high level of safety and effectiveness within an organization. Application of HIRA with target-based control measures can prove to be a lifesaver in some cases. It is all about process risks, equipment risks and/or human factor impact risks. In this phase, potential risks are determined through physical checks and/or documentation deviations, which are deficiencies in procedures for handling or the like. The second step involves analysis of risks from the hazard identification step. In this phase, the identified hazards are analyzed in terms of various effects, i.e., human safety, environmental disturbance and damage to assets/loss of production. The hazardous events are further examined by risk ranking. Steps, when required, are taken for the accountable party to implement and document by writing to prove completion and action close-out.