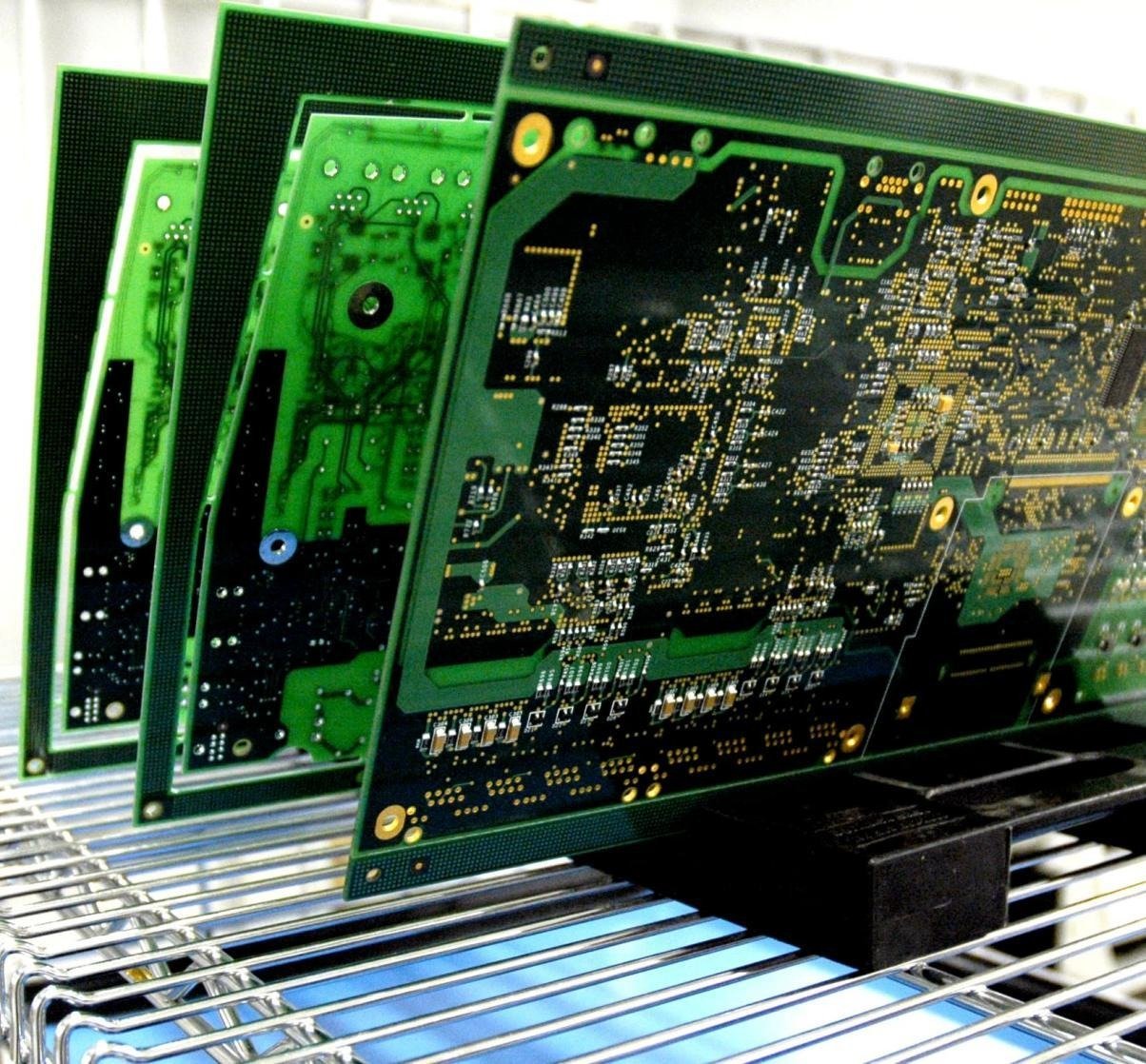

Turnkey PCBA for Small-Batch Production: Fast, Reliable Full-Turnkey PCB Assembly Solutions

Speed and reliability define success in today’s electronics market. For engineers, startups, and manufacturers working on prototypes or small batches, managing multiple suppliers can slow things down and add stress. Turnkey PCBA streamlines this, offering a one-stop solution for the entire process.

This article covers what a turnkey PCBA is, why it suits small-batch production, the process steps, and how to pick a good partner.

What Is Turnkey PCBA?

Turnkey PCBA (Printed Circuit Board Assembly) means that one supplier manages every step of the process — from PCB manufacturing and component sourcing to SMT/THT assembly, testing, and shipping. Instead of coordinating several vendors, you work with a single partner who handles the full workflow and ensures consistent quality.

This approach differs from partial turnkey or consignment assembly, in which the customer provides some or all of the components. In a turnkey PCBA, the manufacturer takes care of everything, including sourcing components through authorised distributors, performing engineering checks, and delivering the fully assembled boards.

At Fast Turn PCB, turnkey assembly services cover the full spectrum—from prototype and NPI (new product introduction) to small- and medium-volume production—across board types, including multilayer, HDI, rigid-flex, and high-frequency PCBs.

Why It’s Perfect for Small-Batch and Prototype Builds

For small runs or engineering samples, time and cost control are key. Turnkey PCBA provides three major benefits:

1. Faster lead times.

A single supplier manages the workflow, so there’s no waiting between multiple vendors. Fast Turn PCB offers quick-turn options, including 24–72 hour prototyping and 2-day fabrication, significantly reducing the overall development cycle.

2. Lower total cost.

Turnkey PCBA removes the need to invest in equipment, fixtures, or extra handling. Centralised purchasing also reduces component costs and eliminates rework caused by coordination errors.

3. Consistent quality.

One team manages manufacturing and assembly, ensuring quality and maintaining traceability. Fast Turn PCB’s process includes automated inspection, functional testing, and full production reporting.

For many startups and R&D teams, full turnkey PCB assembly for small batch production is the fastest and most reliable way to move from concept to prototype to market-ready hardware.

See also: e commerce insights mastery techniques

Typical Turnkey PCB Assembly Process

A professional turnkey PCB assembly solution usually follows these steps:

1. Document preparation.

Supply Gerber files, a complete BOM (with MPN and possible substitutes), pick-and-place (CPL) files, assembly drawings, and testing requirements.

2. DFM/DFT review.

The manufacturer performs design-for-manufacturing and design-for-test analysis to detect issues early and suggest design or material improvements.

3. Component sourcing.

Procure all components from verified suppliers. Review availability and lead times, and propose alternative parts if necessary.

4. PCB fabrication.

The boards are produced according to the specified layer count, copper thickness, finish, and material (FR-4, Rogers, high-Tg, or others). Fast Turn PCB supports 4–50 layers, HDI structures, and rigid-flex designs.

5. SMT/THT assembly.

Components are mounted using precision pick-and-place equipment. The process handles 01005 passives, BGA, QFN, CSP, and LGA devices, with optimised reflow and wave soldering profiles.

6. Testing and inspection.

Each assembly passes through SPI, AOI, X-ray, and, when needed, ICT/FCT and burn-in tests to guarantee functionality and reliability.

7. Packaging and traceability.

Every batch is labelled with a barcode and a lot report. Final inspection and traceable reports ensure full accountability.

8. Project management.

A dedicated project manager oversees every stage, from engineering review to final shipment, and provides customers with real-time updates for peace of mind.

What Affects Cost and Delivery Time

Even with an efficient turnkey process, a few factors can influence pricing and lead time:

- BOM availability: Obsolete or long-lead components may require replacements or split shipments.

- Design complexity: High layer counts, fine-pitch BGAs, or microvias increase production time.

- Testing coverage: ICT and functional testing improve quality but require extra setup.

- Data completeness: Providing full, accurate files at the start avoids engineering delays.

- Batch size and tooling: Shared panels or stencil optimisation can lower small-batch costs.

Fast Turn PCB helps customers manage these challenges through flexible scheduling, engineering feedback, and cost optimisation programs.

Choosing the Right Turnkey Partner

When evaluating a turnkey PCBA supplier, look for these key factors:

- End-to-end capability — Can they handle PCB fabrication, sourcing, assembly, and testing in-house?

- Fast delivery — Do they offer quick-turn options, such as 24-hour or 2-day fabrication?

- Technical range — Can they assemble micro components (01005, BGA, CSP) and complex boards (HDI, rigid-flex, RF)?

- Quality certifications — ISO 9001, ISO 13485, UL, and RoHS/REACH compliance.

- Project management — Dedicated engineers and 24/7 technical support.

- Cost transparency — Authorised sourcing channels and clear quoting processes.

These are the hallmarks of a trustworthy turnkey PCB assembly solution provider.

What You Should Prepare Before Ordering

To make your first order smooth and efficient, prepare these materials:

- Gerber files with clear layer stackup and finish details.

- BOM with manufacturer part numbers (MPN), alternatives, and special notes.

- Pick-and-place file (CPL) and assembly drawings.

- Testing instructions and performance requirements.

- Priority notes such as non-substitutable parts or functional-critical components.

- Optional: expected delivery date, batch quantity plan, and budget range.

Well-prepared data lets the factory quote faster, prevents miscommunication, and starts production sooner.

Why Choose Fast Turn PCB

Fast Turn PCB provides turnkey PCBA services from prototype to production under one roof. The company operates advanced SMT lines and PCB manufacturing facilities that support a wide range of technologies — from multilayer HDI to high-frequency materials.

Key highlights:

- Speed: quick-turn prototypes from 1 piece, 72-hour assembly, and 2-day fabrication.

- Capability: support for 01005, BGA, QFN, CSP, and LGA components.

- Quality: ISO 9001, ISO 13485, UL, RoHS, and REACH certified.

- Reliability: full process traceability, automated testing, and end-to-end documentation.

- Service: one-on-one project managers, instant engineering support, and global shipping.

These features make Fast Turn PCB a trusted partner for engineers and product teams worldwide who want fast, flexible, and reliable turnkey PCBA for prototypes and small-batch production.

Conclusion

For small-batch or prototype projects, turnkey PCBA offers a smarter way to build — combining speed, consistency, and simplicity. By choosing an experienced partner like Fast Turn PCB, you can move from design to production faster, avoid sourcing headaches, and focus on what matters most: launching your next product successfully.